Originally published at: https://knowledge.axminster.co.uk/axminster-trade-clamp-competition/

Win a selection of Axminster Trade Clamps worth £90 in our Axminster Clamp Competition! Simply upload a picture of your clamps in action for a chance to win.

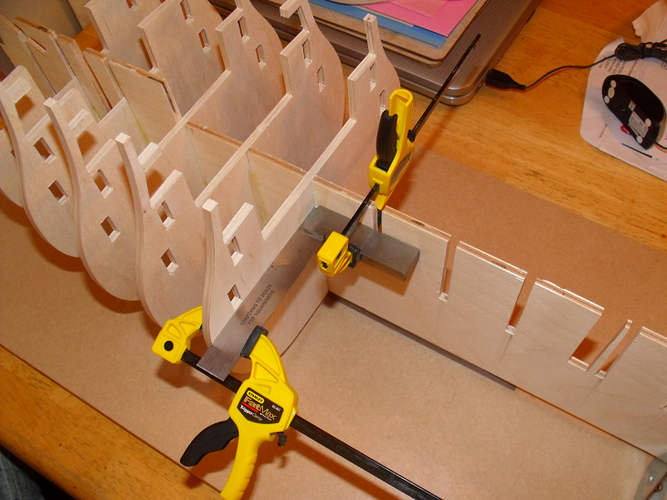

Here’s my current clamping project, 10’ SUP (Stand Up Paddle Board)

6’’ spring clamps and home made waste pipe spring clamps.

You can never have too many clamps!! #AxminsterTradeClamps

Hate to be the one to point this out BR, but those are Stanley ‘Fat Max’ clamps. Look at the T&C…it do say:

“Picking the Winner

The winner will be picked by a team of judges who will be looking for an interesting well-made project with Axminster Trade Clamps in use”

The wife would like to point out that you have just cost her to loose out on a new pair of shoes because her husband now has to go and buy some Axminster branded clams for future photographs

That’s me in the sticky stuff, nothing new there then

In the garden repairing an old bench based on a Welsh coracle - as ther is never enough clamps this will take me a while.

…or in the kitchen - finding a way to mount the old fashion mincer to a thick modern worktop - my favourite small clamps, I find so many uses for them, even woodworking sometimes.

The current project in the 'shop is a very large Korean style chest of drawers, with eight small and four very large drawers, the biggest of which measures 825 x 200mm deep. Each small drawer slides on a central rail and muntin with the large drawers having a pair each. This presents a problem as for the drawer to run smoothly, each runner/muntin must be dead parallel or it will bind. To that end one runner is fixed and the other can be laterally adjusted as it’s slot screwed with 25mm UJK Washer Headed Pocket Hole Screws

Each of the muntins is glued into a 4mm groove on the inside of the drawer, using small pieces of birch ply:

…so that when the drawer is offered up ‘in situ’ the muntins locate into the groove:

At the rear, the muntins are flush with the back of the drawer and the fixed slide can clearly be seen:

In order to apply pressure to the muntins, Axminster Trade Bar Clamps are used together with a short section of muntin to act as a pressure pad:

The plywood offcuts taped to the front ensure that the clamp pad is located squarely in front of the muntin. When the muntins are glued in place, two pieces of 0.6mm veneer are used on the drawer sides to give adequate clearance. Drawer fronts are screwed in place using Rob Ingham’s technique and it was he who very generously took time out to explain clearly to me his method of making and fitting these types of drawers.

Epic fail  Stu, read the T&C, you’ve made the same goof as Big Red!

Stu, read the T&C, you’ve made the same goof as Big Red!

It wasn’t a goof, it was a desperate attempt to convince the lovely people at Axminster know that I need new clamps

…I dont actually have any Axminster trade clamps, so regardless, thought I would enter this…you never know perhaps they might let me have a discount so i can actually buy some…

Like your work BigRed…

Stu, they’re not Axminster Trade Clamps which are required under the terms and conditions of the comp. Just for the record, a direct quote from the relevant Ax page:

‘Picking the Winner

The winner will be picked by a team of judges who will be looking for an interesting well-made project with Axminster Trade Clamps in use’

(you appear to have amended your original post just prior to this one)

I’m sure you’ll win hands down woodbloke…no doubt your project is the most interesting and well made there is…

Not a chance Stu, but I thought people might be interested in how that particular little issue on the current project was solved. I could have used standard sash cramps but they’re a bit too heavy for that application, so the single handed, lighter weight jobbies were ideal. Sarcasm noted.

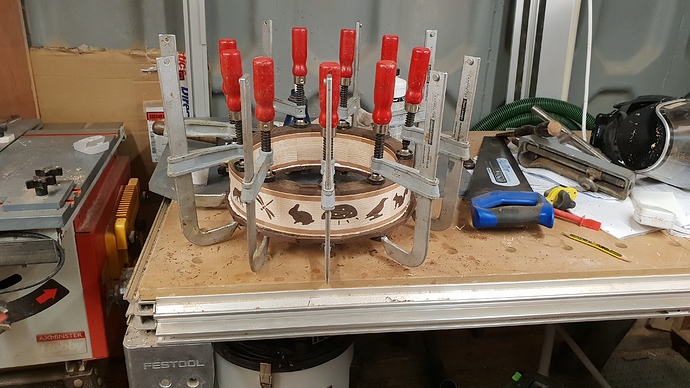

Axminster f clamps my go to clamps for my segmented turning. Here i am using them to glue up a feature ring for my current segmented bowl currentley in production!

We have run out of clamps making our new work benches for our Mens Shed!!

It will just take longer using those we have then all our members will have somewhere to work.

#AxminsterTradeClamps

I just want to show off my f clamp a spotted in an antique shop for 5 pounds  I think it’s a Bessey? never used axminsters clamps but I could do with some strong sash clamps.

I think it’s a Bessey? never used axminsters clamps but I could do with some strong sash clamps.